Established in 1983, Phoenix Inspection Systems are specialists in design and manufacture of ultrasonic non-destructive testing (NDT) solutions serving a wide range of industry sectors including nuclear and power generation, offshore oil, gas and petrochemical, aerospace, composites and rail. The products take into account the full range of ultrasonic NDT techniques, including phased array, corrosion mapping, pulse echo and TOFD and are built to the internationally recognised Quality Management Systems standard ISO 9001:2008.

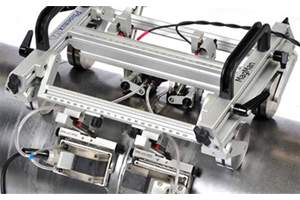

The highly versatile MagMan now features fourth generation upgrades to make this manual weld inspection scanner even easier to use in the field. MagMan can hold twelve probes, so is ideal for inspections requiring a combination of phased array and one or more TOFD pairs or multiple UT probes and can be configured to inspect pipe welds from 2” OD circumferential and 9” OD longitudinal up to flat on ferromagnetic material.

Download BrochureKey Features

- Versatile solution holding up to 12 probe combinations of phased array, TOFD and conventional UT.

- Adaptable scanner covers from 2” OD circ and 9” OD seam welds, up to flat.

- User-friendly quick release adjustments for ease of use in the field.

- Accurate PCS measurement using new increment rails

- Customisable with a wide range of accessories or for bespoke applications.

- Robust construction for site conditions.

- Compatible with any manufacturers probes, wedges and flaw detectors.

Specifications

- Holds from 2 up to 12 probes

- Quick release adjustments throughout

- Frame incorporates three measurement rules for accurate probe separation

- Probes independently sprung and gimballed

- Independent suspension on all 4 magnetic wheels for uneven surfaces

- Accurate tracking via guide chain or laser

- Water-proof, spring-loaded wheel encoder

- Compact design: 350mm x 325mm

- Lightweight yet robust aluminium frame: 3kg