Zetec is the leader in tubing rotating probes technology. We are backed by our nearly 50 years as the global leader in developing NDT solutions for the critical inspection needs of the world’s major industries. Our expertise in developing technological solutions combined with our extensive field experience puts us in a unique position to understand your specific needs. Our rotating probes will provide you with the data necessary for you to make intelligent decisions.

We have created and developed thousands of probe designs successful at identifying and characterizing flaws across a range of applications. In addition to providing you with the rotating probe technology for your inspection solutions, we have track a record of providing support to our clients due to unforeseen issues that have arisen during the inspection process. As NDT industry leaders and inspection technology innovators, the experts at Zetec are your trusted advisers for your NDT solution needs.

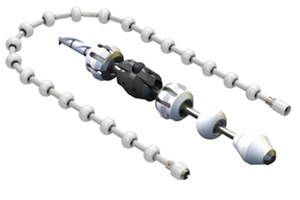

Motor Units

Our high-speed/high-torque MRPC motor units have consistent rotation rates and increased motor torque to spin probe heads and shafts through restrictive tube areas. Designs exist for use with numerous instruments and probe heads. Motor units used with Zetec's MIZ-8x or MIZ-200 products use MIZ-iD technology. This allows tuning parameters to automatically be set, avoiding potential damage to the instrumentation. Many different RPM options are available.

Delta Head MRPC Probes

Zetec's world class manufacturing facility provides quality Delta Head probes with 1, 2 or 3 coils. Both plus point and pancake coils can be provided on the same probe head. For tube permeability variances any of the coils can be magnetically biased. The coils are protected by Zetec's proprietary ZM1 material provided extremely long life for the probe heads.

Rotating Probes for Bends

Zetec' provides a complete line of rotating probe heads for tubing with bends. The Flex Head probe provides the data quality you need by allowing surface riding coils to navigate tight tube bends. Zetec's extension shafts allow for consistent data to be collected when motor units cannot get close enough to the area that needs to be inspected.